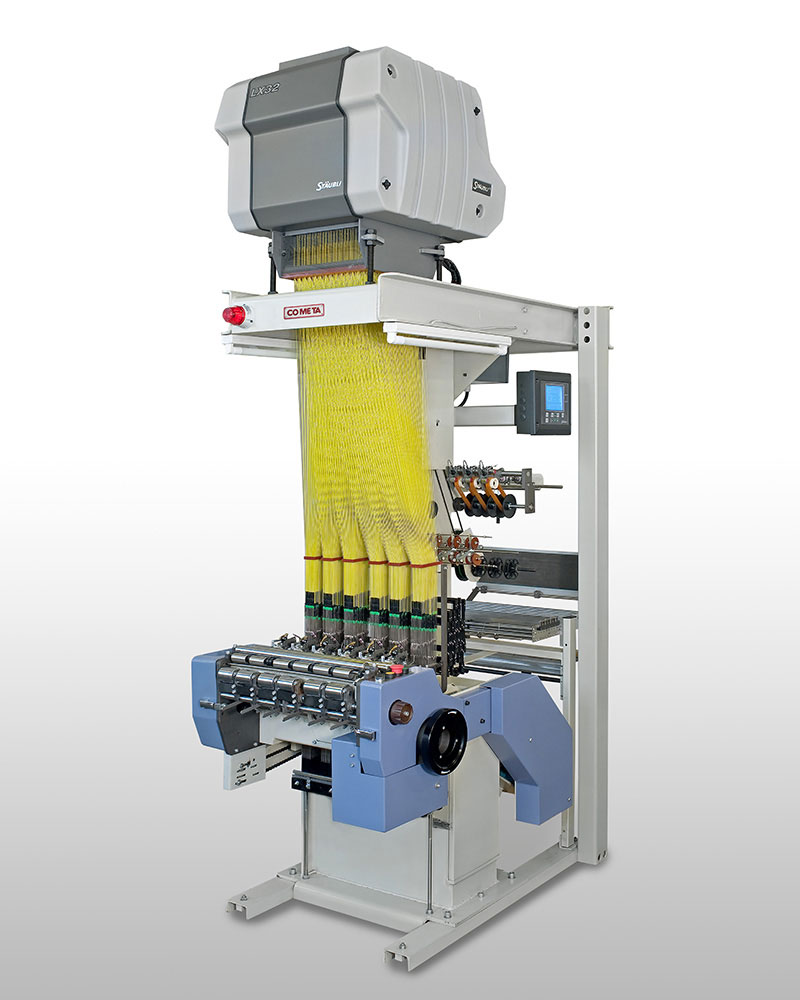

TN-J / TN-JS

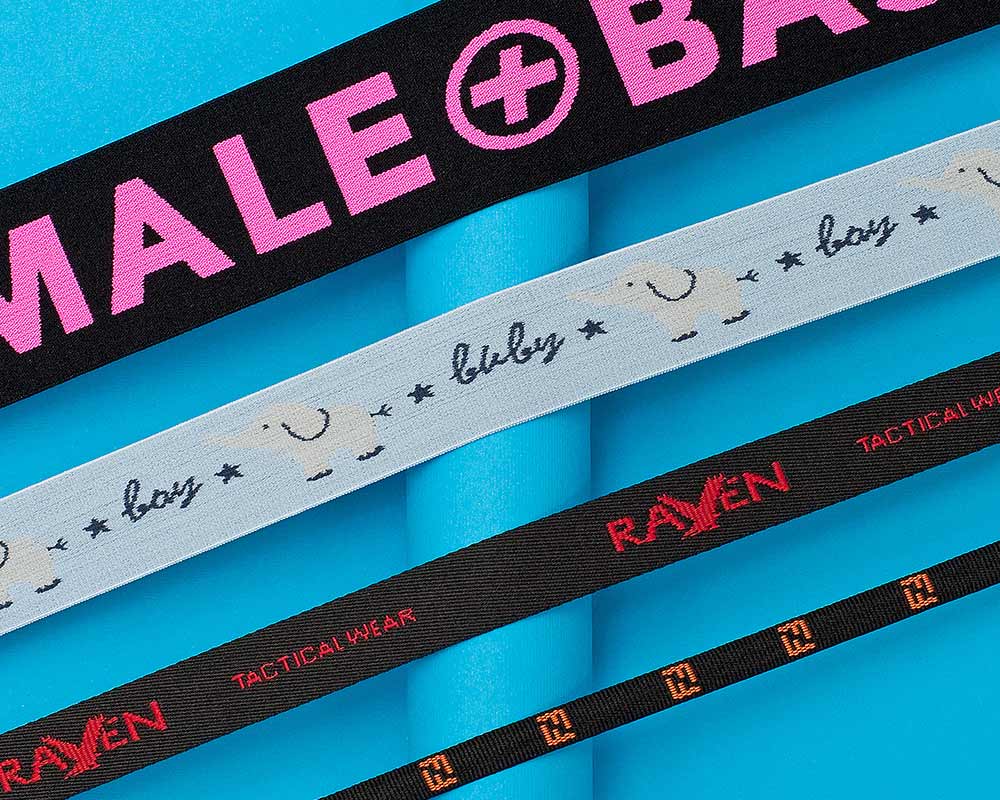

Jacquard needle loom for narrow fabrics

Weaving machine suitable to produce elastic and non-elastic fabrics, such as underwear ribbons, laces, ribbons for garments, ribbons for gift, ribbons for shoes industries, handbags, sportswear ribbons, decorative tapes.

– Available from 192 to 896 hooks

– Available with 12 frames

– Adjustable speed control with inverter is standard. It permits to find and adjust the right speed for each type of product and yarn quality. The inverter permits also the slow motion for operations of check-up and fine adjustment

– The PC on board very easy to use permits to change weaving direction and load new patterns with USB key

– Reliable Jacquard magnets with excellent value for money

– Fully opening frame structure

– Central drive of frame in order to reduce vibrations and stress

– Available with double weft, lateral picot

– Weaving system: 1-2-3

– Special Jacquard CAD available

– Proven construction

– Optimization of movements

– Mechanical precision manufacturing

– CE conformity

– Excellent value for money

DEVICES ON REQUEST

Double take-off

Double weft

Double weft and double needle

Rubber feeder

Creel for beams 355×310 20 pos.

Creel for beams 355×310 14 pos.

Beam 302×260 – 001

Beam 355×255 – 003

TN-53/70/80

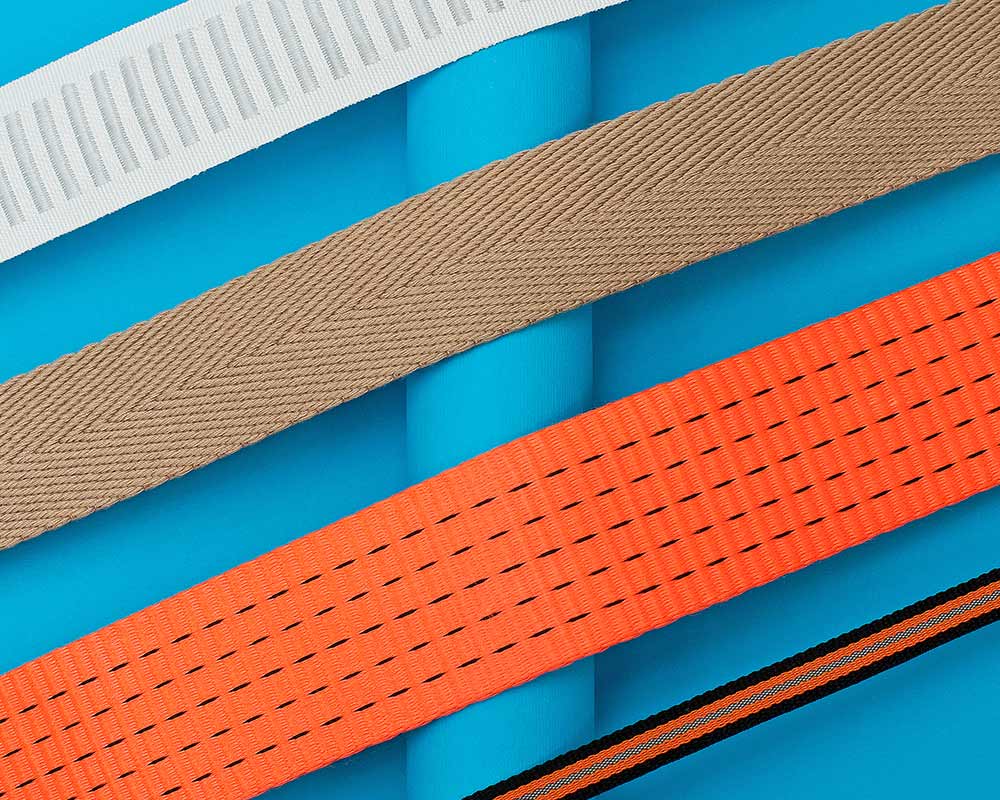

Loom for lightweight and medium weight narrow fabrics

Weaving machine suitable to produce elastic and non-elastic fabrics, such as underwear ribbons, laces, zipper tapes, ribbons for garments, ribbons for gift, ribbons for shoes industries, handbags, medical articles, sportswear ribbons, curtains tapes, decorative tapes, tapes to print.

– Number of frame available from 12 to 20

– Adjustable speed control with inverter is standard. It permits to find and adjust the right speed for each type of product and yarn quality. The inverter permits also the slow motion for operations of check-up and fine adjustment

– Fully opening frame structure

– Central drive of frame in order to reduce vibration and stress

– Available with double weft, picot.

– Weaving system: 1-2-3

– Possibility, under request, to connect a Data Control touch screen

– Proven construction

– Optimization of movements

– Use of quality materials

– CE conformity

– Excellent value for money

DEVICES ON REQUEST

N°2 frames

N°4 frames

N°6 frames

N°8 frames

Double take-off

Double weft

Double weft and double needle

Picot PT5

Rubber feeder

Creel for beams 355×310 20 pos.

Creel for beams 355×310 14 pos.

Beam 302×260 –001

Beam 355×255 –003

Weft feeding with IRO

TN-L

Loom for lightweight narrow fabrics

Weaving machine suitable to produce elastic and non-elastic fabrics, such as underwear ribbons, laces, zipper tapes, ribbons for garments, ribbons for gift, ribbons for shoes industries, handbags, medical articles, sportswear ribbons, curtains tapes, decorative tapes, tapes to print.

– Number of frame available from 8 to 16

– Fully opening frame structure

– Central drive of frame in order to reduce vibration and stress

– Available with double weft, picot.

– Weaving system: 1-2-3

– Proven construction

– Optimization of movements

– Mechanical precision manufacturing

– CE conformity

– Excellent value for money

DEVICES ON DEMAND

Rubber feeder

Creel for beams 355×310 20 pos.

Creel for beams 355×310 14 pos.

Beam 302×260 –001

Beam 355×255 –003

TN-53/170/210/310

Loom for lightweight and medium weight narrow fabrics

Weaving machine suitable to produce elastic and non-elastic fabrics, such as underwear ribbons, laces, zipper tapes, ribbons for garments, ribbons for gift, ribbons for shoes industries, handbags, medical articles, sportswear ribbons, curtains tapes, decorative tapes, tapes to print.

– Number of frame available from 12 to 18

– Available with 2 heads for reed width in mm of 170/210/310

– Adjustable speed control with inverter is standard. It permits to find and adjust the right speed for each type of product and yarn quality. The inverter permits also the slow motion for operations of check-up and fine adjustment

– Fully opening frame structure

– Central drive of frame in order to reduce vibration and stress

– Weaving system: 1-2-3

– Possibility, under request, to connect a Data Control touch screen

– Proven construction

– Double take-off

– Optimization of movements

– Mechanical precision manufacturing

– CE conformity

– Excellent value for money

DEVICES ON REQUEST

N°2 frames

N°4 frames

N°6 frames

N°8 frames

Double weft

Double weft and double needle

Rubber feeder

Creel for beams 355×310 20 pos.

Creel for beams 355×310 14 pos.

Beam 302×260 –001

Beam 355×255 –003

Weft feeding with IRO

TN-RR 53

Needle loom for the production of belts for furniture

Needle loom at 2 or 4 heads for elastic tapes combined with a crochet machine used to produce belts for furniture.

– 8 frames

– 4 heads 66 mm reed or 2 heads 84 mm reed

– Specific reinforcements for heavy elastic tapes

– Brushless main motor CA/E

– Take off with backstop A/E

– 3 rollers feeder A/E

– Start-stop-jog board

– Speed regulation of all the motors by touch screen data control

– Machine is supplied with a slow motion function to regulate and control the weaving operation

– Weaving system: 1

– Available, under request, front collecting device for final product on circular rolls

FEATURES OF CROCHET MA CHINE COMPLETE WITH

Brushless main motor A/E

Take off with backstop A/E

3 rollers pre-feeder for elastic threads C/T

3 rollers feeder for elastic threads A/E

Grooved bar for elastic threads

Needle bed gauge 8,5 with 133 bearded needles

All the regulations are electronic A/E by simple synchronization from touch screen

Proven construction

Optimization of movements

Use of quality materials

CE conformity

Excellent value for money

T-600

Rapier loom 600 mm

Weaving loom suitable to produce elastic and non-elastic wide fabrics for various kind of applications.

– Number of frame available up to 12

– Available with 1 head for reed width 600 mm or 2 heads for reeds width 300mm

– Adjustable speed control with inverter is standard. It permits to find and adjust the right speed for each type of product and yarn quality

– The inverter permits also the slow motion for operations of che ck-up and fine adjustment

– Fully opening frame structure

– Central drive of frame in order to reduce vibration and stress

– Weaving system: 1-2

– Chain links repetitions 8-48

– Electronic take down device

– Data Control touch screen

– Proven construction

– Optimization of movements

– Use of quality materials

– CE conformity

– Motor power 1,5 Kw

DEVICES ON REQUEST

Weft feeding IRO type

Rubber feeder

Creel for beams 20 positions

Creel for beams 14 positions