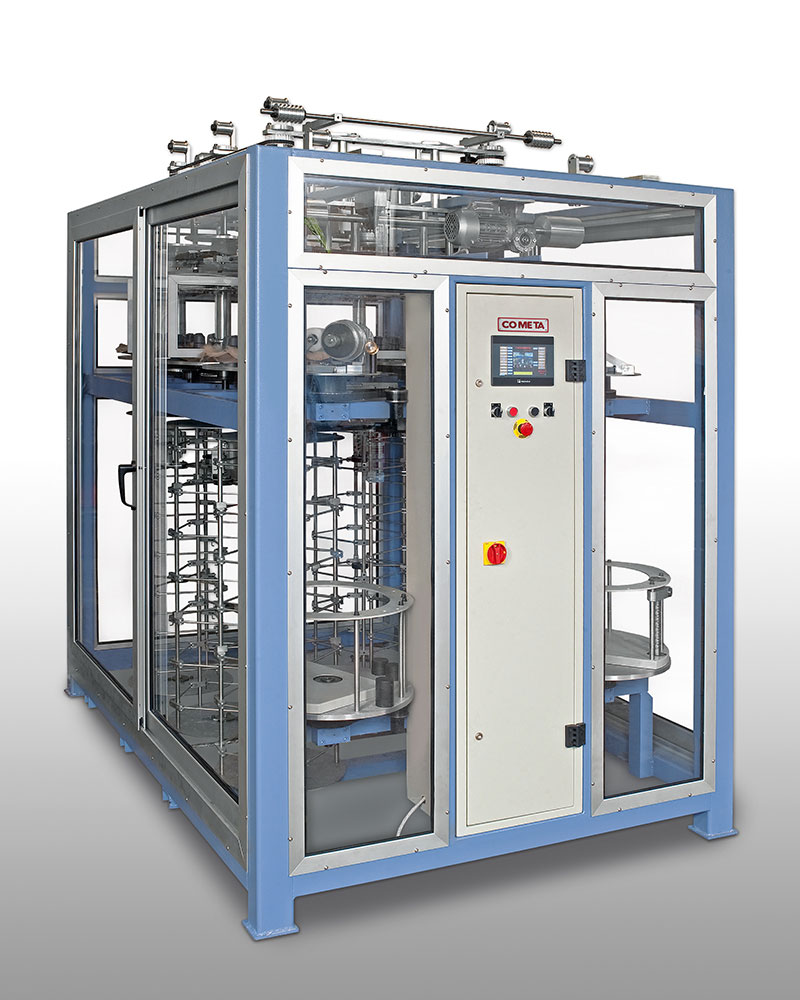

T106/6

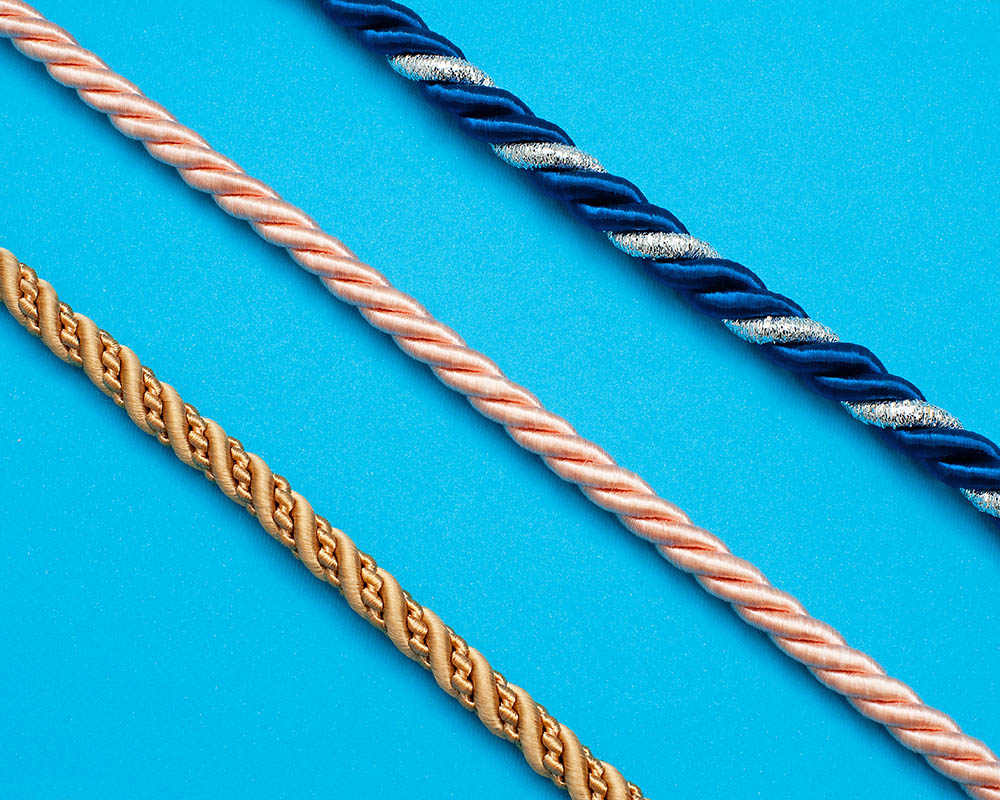

Cords

ELECTRONIC machine suitable for the production of 2 cords with 3 heads, simultaneously, from 5 to 20 mm diameter.

T 106/6 has the option on each twisting devices to mount up to 28 spools for rotating core creel.

It is also possible to use any type of yarn, also of recovery, which will form the core of the cord, recovered by 8 bobbins truncated cones.

T 106/6 has 6 twisting devices that can be loaded with yarns of the different colors, so to obtain a nice effect of vivid colors alternating between them. The production of the various diameters of the final cords, between 3 and 20 mm., will be determined by the amount of yarns used for each core and by the various twists applied to the heads.

T 106/6 on request is possible, with the use of a particular kit, to perform the production of 1 cord with 4 heads.

T 106/6 is provided with core guide bushings diameter of 8 mm and on request, the user can ask also the diameter 3 mm and 5 mm.

T 106/6 is provided with an electronic system for the control of the speed changes of the twisting devices, of the torsion and tension for the production of the cord, supported by a PLC of new conception, simple and efficient. It is already on the machine and is equipped with a keyboard and display for viewing and programming data. The PLC stores for each product code the speed

of twisting devices, the upper take down, the take down of the twisting plate, the eventual folding, the final diameter of the product, as well as the color of the same, the rotation direction, the diameter of the cord, the number of bobbins and denier of covering yarn.

The above data, as well as being stored in memory, are kept constantly under control during production. To all this, we have to add that the same PLC also check the integrity of the yarns covering of the cord.

T 106/6 is provided with 4 cylindrical box for the collection of cordons of small diameter and with a meter counter with preselection that gives indicatively the production according to the diameter and twisting.

T 106/6 on request is provided with a collector device of the product on bobbins.

T 106/6 by a check panel on board controls the operation of the doors avoiding opening up to the total stopping of the moving parts in the machine and preventing, in the case of the open door, the start up for the cycle production in compliance with current EC standards.

T 106/6 IS SUPPLIED COMPLETE WITH:

– PLC programming for machine

– Meter counter with preselector

– Stop motion machine device for breaking covering yarns

– 6 covering plates

– 6 core rotation creels

– 2 twister plates

– 4 box for product collection

DEVICES ON REQUEST

17. **. 160250 Collection system 1-2 small bobbins collector

17. **. 300250 Collection system 1-2 big bobbins collector

13.050.24.160 Small bobbins diam. 240 h 160mm

13.050.24.300 Big bobbins diam. 240 h 320mm

17.04.160.250 Cord rewind system

17.00.000 *.00 Griffé (for heads)

TC40.30339 Core guide diam. 3

TC40.30072 Core guide diam. 5

17.04.160.004 Kit for 4 heads cords

T212/4

Cords

ELECTRONIC machine suitable for the production of 1 cord with 3/4 heads, simultaneously, from 12 to 35 mm diameter.

T 212/4 has the option on each twisting devices to mount up to 54 spools for rotating core creel.

It is also possible to use any type of yarn, also of recovery, which will form the core of the cord, recovered by 12 bobbins truncated cones.

T 212/4 has 4 twisting devices that can be loaded with yarns of the different colors, so to obtain a nice effect of vivid colors alternating between them. The production of the various diameters of the final cords, between 12 and 35 mm., will be determined by the amount of yarns used for each core and by the various twists applied to the heads.

T 212/4 is provided with an electronic system for the control of the speed changes of the twisting devices, of the torsion and tension for the production of the cord, supported by a PLC of new conception, simple and efficient. It is already on the machine and is equipped with a keyboard and display for viewing and programming data. The PLC stores for each product code the speed

of twisting devices, the upper take down, the take down of the twisting plate, the eventual folding, the final diameter of the product, as well as the color of the same, the rotation direction, the diameter of the cord, the number of bobbins and denier of covering yarn.

The above data, as well as being stored in memory, are kept constantly under control during production. To all this, we have to add that the same PLC also check the integrity of the yarns covering of the cord.

T 212/4 is provided with 2 cylindrical box for the collection of cordons of small diameter and with a meter counter with preselection that gives indicatively the production according to the diameter and twisting.

T 212/4 on request is provided with a collector device of the product on bobbins.

T 212/4 by a check panel on board controls the operation of the doors avoiding opening up to the total stopping of the moving parts in the machine and preventing, in the case of the open door, the start up for the cycle production in compliance with current EC standards.

T 212/4 IS SUPPLIED COMPLETE WITH:

– PLC programming for machine

– Meter counter with preselector

– Stop motion machine device for breaking covering yarns

– 4 covering plates

– 4 core rotation creels

– 1 twister plates

– 2 box for product collection

DEVICES ON REQUEST

– Collection system 1 big bobbins collector

– Big bobbins diam. 240 h 320mm

– Cord rewind system

– Griffé (for heads)

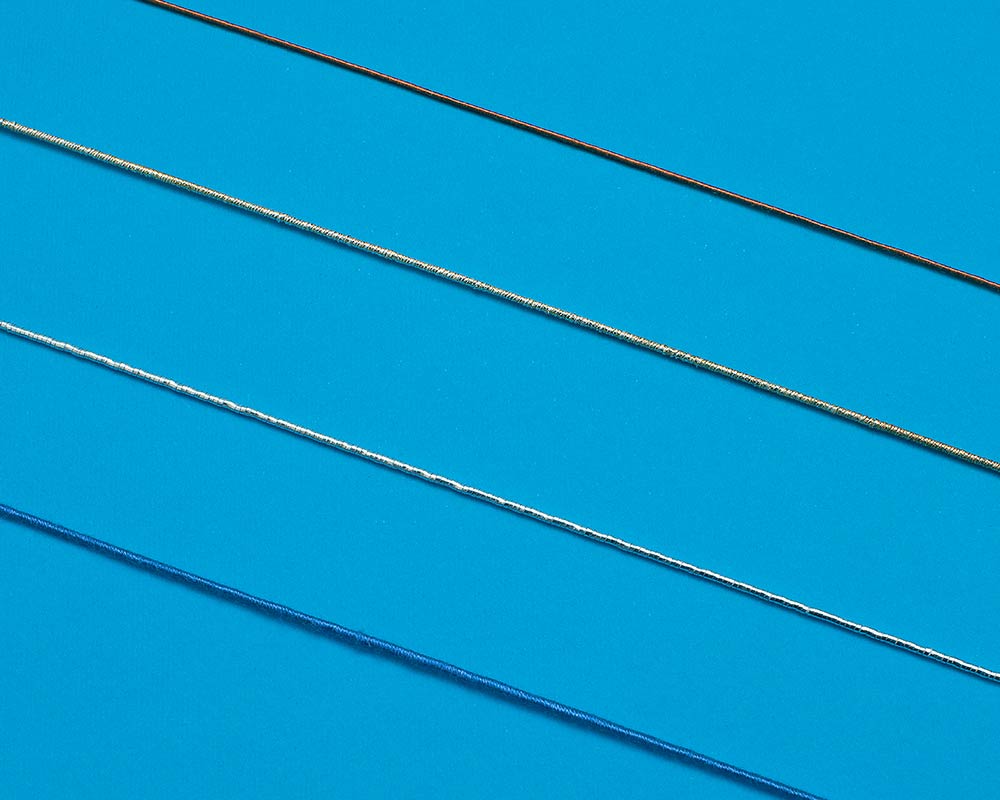

PENELOPE 3

Cords

High speed SEMI-ELECTRONIC spiral covering machine with 3 independent heads suitable for the production of “gimp” i.e. covered yarn.

PENELOPE 3 is provided with a selector for the control and management of 3 heads and independent stop of the covering spindles.

PENELOPE 3 is driven by 3 separate motors that allow a marked working flexibility in every circumstance.

PENELOPE 3 is provided with an INVERTER for the machine speed rotation adjustment between 0 and 15.000 rpm.

The finished product is winded on cylindrical bobbins.

It is possible to produce 3 identical gimps thanks to the collector device and the stitch density regulator device that are working simultaneously.

PENELOPE 3 MACHINE IS SUPPLIED COMPLETE WITH:

– 3 feeding wheels

– 3 product collectors

– Adjustable folding device

PENELOPE 3 Plus

Cords

High speed SEMI-ELECTRONIC spiral covering machine with 3 independent heads versatile and highly functional suitable for the production of strings and cords with and without covering in different diameters between 1 and 4 mm both in 2/3 heads created in a single working section and “classical gimp”, i.e. covered yarn and twisted gimp with right and left rotation collected in standard cones.

The different dynamic functions of PENELOPE 3 PLUS make it suitable for the production of different types of products; its versatility and simplicity get a good level of production compared to the existing standard, reaching 7 meters/ minute for the cord.

PENELOPE 3 PLUS is provided with a selector for the control and management of 3 heads and independent stop of the covering spindles.

PENELOPE 3 PLUS is driven by separate motors that allow a marked working flexibility in every circumstance.

PENELOPE 3 PLUS is provided with an INVERTER for the machine speed rotation adjustment between 0 and 15.000 rpm.

The finished product is winded on cylindrical bobbins.

PENELOPE 3 PLUS MACHINE IS SUPPLIED COMPLETE WITH:

– 3 feeding wheels

– 3 product collector for gimp with adjustable folding device

– 1 product collector for cord

– 6 cones for covering spindles

– 2 cones for cord

– 3 cones for gimp collection

PENELOPE 3 Max

Cords

High speed SEMI-ELECTRONIC spiral covering machine with 3 independent heads versatile and highly functional suitable for the production of strings and cords with and without covering in different diameters between 5 and 10 mm both in 2/3 heads created in a single working section and “classical gimp”, i.e. covered yarn and twisted gimp with right and left rotation collected in standard cones.

The different dynamic functions of PENELOPE 3 Max make it suitable for the production of different types of products; its versatility and simplicity get a good level of production compared to the existing standard, reaching 7 meters/minute for the cord.

PENELOPE 3 Max is provided with a selector for the control and management of 3 heads and independent stop of the covering spindles.

PENELOPE 3 Max is driven by separate motors that allow a marked working flexibility in every circumstance.

PENELOPE 3 Max is provided with an INVERTER for the machine speed rotation adjustment between 0 and 15.000 rpm.

The finished product is winded on cylindrical bobbins for gimp or on flanged bobbin for cord.

PENELOPE 3 Max MACHINE IS SUPPLIED COMPLETE WITH:

– 3 feeding wheels

– 3 product collector for gimp with adjustable folding device

– 1 product collector for cord

– 3 9 positions creels for each covering spindle

– 2 cones for cord

– 3 cones for gimp collection

ISOTTA

Cords

ISOTTA a very versatile and high quality spooling machine.

It is equipped with 2 heads and it is possible to control the spira-step and the cones speed rotation.

It is suitable for matching 1 or more yarns in the cones used for the gimp.

With ISOTTA there is the possibility to wind even small cords on cones of different sizes and models.

ISOTTA is complete of a rear creel for a correct and best arrangement of the product.

IRIS 3

Cords

ELECTRONIC twisting machine for the production of one strand twisted cords.

IRIS 3 with the addition of a particular device is also suitable for the production of normal cords on 2-3 strands in two distinct working phases.

IRIS 3 has 3 independent twisting heads; each head is composed by yarn feeder, meters counter and twisting device. By means of a selector each single head can be excluded according to the user’s needs.

IRIS 3 is the result of a constant research in the sector of textile machinery, looms, twisting machines to which is added a perfect knowledge of the electronic applications that permitted the achievement of an avant-garde in the traditional domestic and overseas market.

IRIS 3 can fit bobbins with a 250 mm. diameter and 200 mm.width. To collect a greater quantity of product and a greater autonomy of the machine can be fitted smaller diameters bobbins without compromising the proper functioning of the machine.

IRIS 3 can also be provided of creel for 60 cone bobbins with 130 mm diameter for covering and 42 cylindrical cones with 130 mm diameter for the core getting a strand with a maximum diameter of 6 mm.

IRIS 3 has an electronic control for managing, by setting the diameter and twisting cord, the automatic brake regulation that changing the cones diameter increases or decreases the brake work effort. Using the control panel on the machine you can manage the operation of the doors preventing the opening up to the total stopping of the moving parts in the machine and preventing, in the case of the open door, the start-up cycle for the production in accordance with

EC standards.

IRIS 3 MACHINE IS SUPPLIED COMPLETE WITH:

– Electronic control board machine

– PLC twisting program

– 3 independent heads

– 3 selectors for exclusion of each single head

– 3 positive core yarns feeder

– 3 meters counter

– 6 cylindrical cones

– Adjustable anti-vibration feet

– General stop and safety machine device in accordance with EC standards.

DEVICES ON REQUEST

60.00000.03.084 Tensioning device for covering yarns and yarn brake stop

70.00025.03.000 Creel

60.00000.03.000 Assembling strands device for making cords

13.050.24.200 Bobbin for twisting device

30.0035.0000.00 Assembled brake